What’s the difference? What is Annealed, Heat Strengthened and Tempered Glass anyway?

Annealed, Heat Strengthened and Tempered Glass are the three main types of glass used in buildings around the world. Each type of glass has it’s own characteristics such as strength, breakage pattern and cost.In this article, we will review each type briefly to get a good grasp on what glass may be right for your Windows and Doors, or to understand what glass you currently have in your home or condo.

Annealed glass is “regular” glass that comes from the glass manufacture and is sometimes refereed to as “float” glass. Annealed glass is the weakest of the three types, and care should be given when choosing a location for this glass.

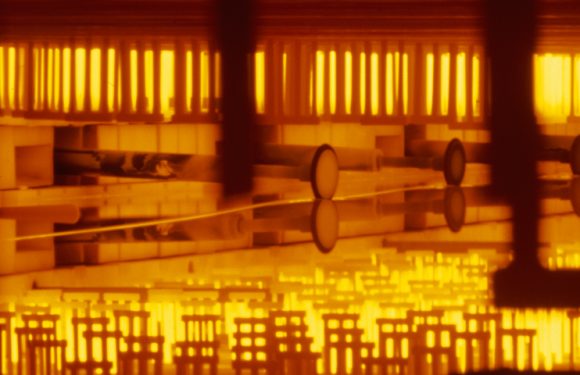

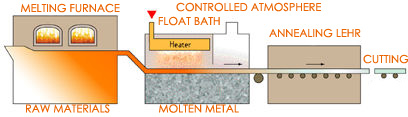

How is annealed glass made?

When you melt silica sand, limestone, soda ash, salt cake and dolomite at 2700 degrees Fahrenheit, you get liquid glass. This liquid is then floated on a pool of molten tin, and why it is also refereed to as “float glass”. It’s then pulled onto a conveyor belt and heated by a special furnace or “lehr” to bring the temperature of the new glass down slowly, and without creating tension. After proper cooling, this glass is cut into large sheets and shipped off to other manufactures to be tempered, heat strengthening or cut and put to use as is.

Annealed Glass breakage, strength and cost

Of the three different types of glass, annealed is the weakest. When annealed glass is impacted with an object, it cracks in large sharp pieces. That makes this glass dangerous to use in areas that are prone to bumping, slamming and where there is a slip hazard that could send someone smashing into it. Because this glass is the “rawest” form used in windows and doors, it is also the cheapest. I would consider this for use in closets and small openings at higher elevations that can’t be reached or put in harms way.

Heat Strengthened Glass is Annealed Glass that has been heat treated to make it more tolerable to rapid temperature changes and offer more strength than it’s original annealed form. Even though it is stronger than annealed glass, you still must be careful where this glass is used.

How is heat strengthened glass made?

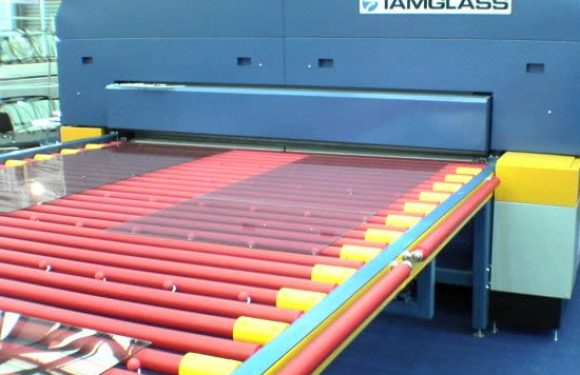

Once the annealed glass has been made and cooled, it is possible to heat treat this glass to offer more strength. First, the annealed glass is cut to it’s final size, once the glass is heat treated it is harder if not impossible to cut. The the glass is heated to between 1100 – and 1500 degrees Fahrenheit then quickly cooled down. This rapid cool down increased the compression and stress inside the glass and offered more strength. Once the glass has been heat strengthened, it will be approximately twice as strong as annealed glass, however it will also be more brittle.

Heat Strengthened Glass breakage, strength and cost

Even though Heat Strengthened glass is about twice as strong as annealed, it still breaks apart in large sharp chunks. This makes it a bad idea in hazard locations as described with annealed glass. The ideal location is someplace that could use extra strength but isn’t a hazard like bedrooms, living areas or larger windows requiring larger glass units. The cost of this glass is more than annealed glass because of the extra process it goes through. This glass could have some visual distortions because has this glass is re-heated it could slightly warp when cooling and cause what we call “clown glass”. Clown glass is when you look through it is things seem distorted and looks similar to the mirrors used in circus side shows to make you look tall or short.

Clown Glass

Tempered glass is also made from annealed glass. It is the strongest type of the three we discussed here and safe to use in the hazardous areas that require safety glass.

How is tempered glass made?

Tempered Glass is made almost the same way heat treated glass is made. First the annealed glass is cut to finish size, then it is heated in an oven and quickly cooled or “quenched” at rate much faster than heat strengthened glass. When this glass is rapidly cooled, it adds surface and edge tension and compression, adding to it’s strength.

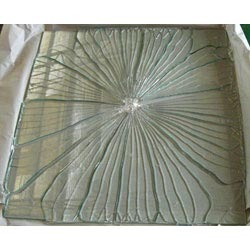

Tempered Glass breakage, strength and cost

When tempered glass is quenched, it created tension and compression all over the glass surface and edges. When tempered glass if broken it sometimes “explodes” and the entire glass piece is broken into little small chunks of glass. This small pieces are not large enough to actually deeply cut you and there are no large or heavy pieces. I personally was removing a 5 foot wide by 13 foot tall 5/8″ thick tempered glass unit that was in an aluminum frame from a home in Naples. It took about 5 guys to move the unit and tip it on it’s side to transport. When we started to lift the glass it hit a screw in the bottom corner and the entire unit exploded and came crashing down on us. Every person walked away with very small scratches here and there but nothing more. If this was an annealed or heat strengthened piece, it could of killed us acting like a guillotine. Tempered glass is safe to use where someone might slip or bump into it like a door, sidelights or bathroom windows. There is also a chance of distortion on tempered glass units just like heat strengthened glass. The cost of this glass is two to three times as much because of the longer and more complicated process that makes it 4 -5 times stronger than annealed glass.

Next time we will talk about how these glass types are used in Hurricane Protection and laminated glass.